If you’re running a bustling kitchen, a catering business, or even just a very active home with serious food preservation needs, investing in the Best Commercial Vacuum Sealer isn’t just a luxury—it’s a game-changer. This powerhouse appliance can revolutionize the way you store, prepare, and manage your food inventory, ensuring everything stays fresher for longer while significantly cutting down on waste. Forget those flimsy countertop models; a commercial vacuum sealer is built for relentless, heavy-duty performance, delivering the kind of airtight seal that keeps your ingredients at their peak.

What is a Commercial Vacuum Sealer and Why Do You Need One?

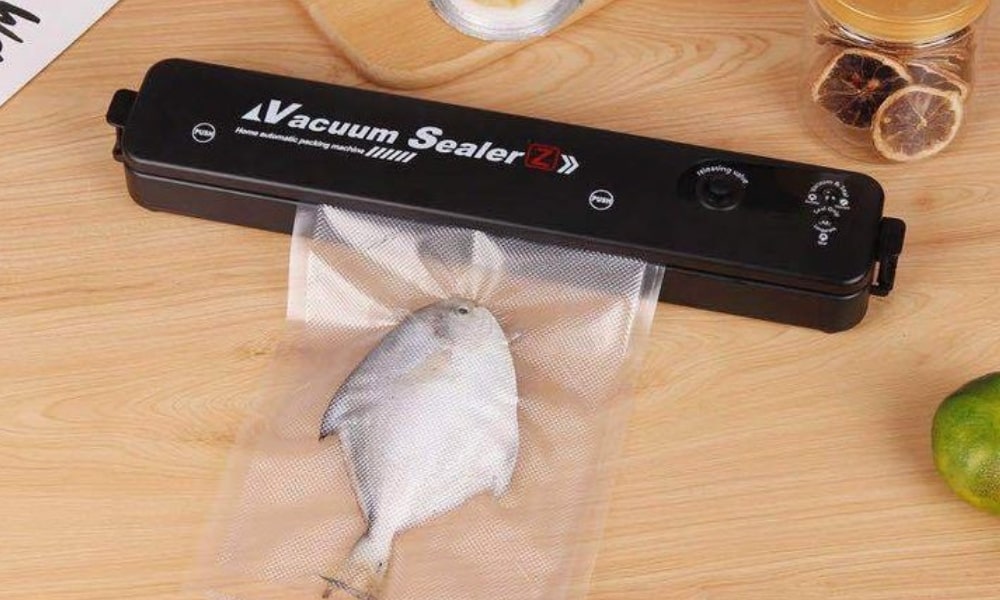

At its core, a vacuum sealer removes air from a bag or container before sealing it tightly. This process dramatically extends the shelf life of food by preventing oxidation and inhibiting the growth of microorganisms like bacteria and mold. But a commercial vacuum sealer takes this fundamental principle to a whole new level.

Unlike consumer-grade models, commercial units are engineered for continuous, high-volume operation. They boast robust construction, typically from durable stainless steel, and feature powerful pumps designed for heavy use without overheating. This distinction is crucial for businesses that rely on consistent performance day in and day out.

Why is this essential for your operation?

- Extended Shelf Life: Vacuum sealing can keep food fresh up to five times longer than traditional storage methods. This means less spoilage and more time to utilize your valuable ingredients.

- Reduced Food Waste: By extending freshness, you’ll throw away less food, leading to significant cost savings and a more sustainable operation.

- Enhanced Food Safety: An airtight seal protects food from contaminants and freezer burn, maintaining quality, flavor, and nutritional value.

- Efficient Inventory Management: You can buy ingredients in bulk, portion them out, and store them efficiently, optimizing your purchasing and storage space.

- Rapid Marination: The vacuum environment forces marinades deeper into meats and vegetables in a fraction of the time, enhancing flavor quickly.

- Sous Vide Preparation: It’s an indispensable tool for sous vide cooking, ensuring perfectly sealed pouches for even, controlled cooking.

Decoding Commercial Vacuum Sealers: Chamber vs. External Models

When it comes to the best commercial vacuum sealer, you’ll primarily encounter two types: external (out-of-chamber) vacuum sealers and chamber vacuum sealers. Each has its strengths, and understanding the differences is key to making the right choice for your business.

External Vacuum Sealers

External vacuum sealers work by placing the open end of a specially designed bag onto a sealing bar, outside the machine itself. The machine then sucks the air directly out of the bag and seals it.

- Pros:

- Lower Initial Cost: Generally more affordable to purchase upfront.

- More Compact: Typically smaller and lighter, making them suitable for kitchens with limited counter space.

- Ideal for Dry Goods: Excellent for sealing solid foods like cured meats, cheese, dry herbs, and pre-portioned ingredients.

- User-Friendly: Often feature simple, intuitive controls.

- Cons:

- Struggle with Liquids: Not ideal for sealing liquids or very moist foods, as the liquid can be drawn into the machine’s pump, potentially damaging it or compromising the seal. Freezing liquids first is often required.

- More Expensive Bags: Require textured or embossed bags, which are generally more costly than the smooth bags used with chamber sealers.

- Limited Continuous Use: Many models, even “commercial grade,” might have a duty cycle that requires cool-down periods, making them less suited for truly continuous, high-volume sealing.

Chamber Vacuum Sealers

Chamber vacuum sealers operate by placing the entire bag inside a vacuum chamber. The machine then removes air from both the chamber and the bag simultaneously.

- Pros:

- Excellent for Liquids: Because pressure is equalized inside the chamber, liquids, marinades, and soups can be sealed without being sucked out of the bag.

- Superior for High Volume: Designed for continuous operation with a 100% duty cycle, making them perfect for busy commercial kitchens.

- Consistent, Professional Seals: Deliver a reliable, airtight seal every time, crucial for food safety and preservation.

- Cheaper Bags in the Long Run: Use smooth, flat vacuum bags, which are significantly less expensive than textured bags, leading to substantial savings over time, especially for high-volume users.

- Versatile: Can also be used to vacuum seal jars and containers, and even infuse liquids.

- Cons:

- Higher Initial Cost: Chamber sealers represent a more significant upfront investment.

- Larger Footprint: They are typically larger and heavier, requiring more dedicated counter or floor space.

Which one is right for you? If your business involves sealing liquids, large volumes of food daily, or requires the utmost consistency and durability, a chamber vacuum sealer is undeniably the superior choice and a worthwhile investment. For lower volume, dry goods, or budget-conscious operations, a heavy-duty external vacuum sealer might suffice, but understand its limitations.

Key Features to Consider When Choosing the Best Commercial Vacuum Sealer

Selecting the best commercial vacuum sealer isn’t just about picking the most expensive one. It’s about finding a machine that perfectly aligns with your operational demands. Here’s what to look for:

Durability and Build Quality

Commercial environments are tough, so your sealer needs to be tougher. Look for:

- Stainless Steel Construction: This is the gold standard for hygiene, durability, and corrosion resistance in a commercial kitchen.

- Powerful Pump Type:

- Oil Pumps: Often found in higher-end chamber sealers, these are workhorses, offering consistent, powerful suction and excellent durability for continuous use. They do require regular oil changes and maintenance.

- Dry Pumps: More common in external sealers and some entry-level chamber models, they are maintenance-free but might not be as robust for constant, heavy use and can be prone to overheating if overtaxed.

- Robust Sealing Bar: A wide, durable sealing bar ensures a strong, consistent seal across various bag types and sizes.

Sealing Performance and Speed

Time is money in a commercial setting.

- Quick Cycle Times: How fast can the machine complete a vacuum and seal cycle? For high-volume operations, every second counts.

- Adjustable Vacuum Levels: The ability to control the vacuum strength is crucial for sealing delicate items without crushing them, or achieving a deep vacuum for dense foods.

Chamber Size / Bag Compatibility

Consider the largest items you typically seal.

- Chamber Dimensions: For chamber sealers, ensure the internal dimensions of the chamber can accommodate your largest bags or containers.

- Bag Width: Check the maximum bag width the sealing bar can handle. Wider bars (e.g., 15-inch) offer more flexibility for bulk items.

Control and Automation

Modern commercial vacuum sealers offer advanced features for precision and ease of use.

- Programmable Settings: Store preset vacuum and seal times for different products to ensure consistency and speed.

- Digital Displays: Provide clear feedback on settings and progress.

- Manual Mode / “Seal Only” Function: Offers greater control, allowing you to stop the vacuum at any point (useful for delicate foods) or simply create a seal without vacuuming.

Ease of Maintenance

A commercial kitchen demands equipment that’s easy to clean and maintain.

- Removable Sealing Bars: Simplify cleaning and gasket inspection.

- Accessible Components: Ensure you can easily access and clean the chamber, lid, and drip tray to prevent food buildup and ensure hygiene.

- Gasket Quality: The gasket is critical for an airtight seal. It should be durable and easy to clean or replace.

Duty Cycle

For serious commercial use, look for a machine with a “100% duty cycle,” meaning it can operate continuously without needing to cool down. This is typically a hallmark of true commercial-grade equipment.

Top Contenders: A Glimpse at Highly-Rated Commercial Vacuum Sealers

When you’re searching for the best commercial vacuum sealer, certain brands and models consistently earn high praise for their durability and performance. While specific models may evolve, the reputation for quality remains. Brands like VacMaster, Weston, and LEM are often cited for their robust commercial offerings.

- VacMaster VP215: Frequently hailed as an excellent all-around chamber vacuum sealer, praised for its oil pump, durability, and ability to handle liquids with ease, making it a staple in many small to medium commercial settings.

- Weston Pro-2300/Pro-3000: These external models are highly regarded for their heavy-duty performance, powerful motors, and wide sealing bars, perfect for large cuts of meat and high-volume dry goods.

- LEM MaxVac Pro: A popular chamber sealer known for its reliable performance and solid build, often recommended for avid hunters and those processing large quantities of food.

- VacPak-It: Offers a range of commercial vacuum sealers, including chamber models like the VMC100P, designed for heavy use in demanding environments.

These examples illustrate the kind of performance and features you should expect from a top-tier commercial unit.

Mastering Your Commercial Vacuum Sealer: Tips for Optimal Use

Getting the most out of your best commercial vacuum sealer involves more than just pressing a button. A few best practices can significantly enhance your results and prolong the life of your machine.

- Choose the Right Bags: Always use high-quality, commercial-grade vacuum sealer bags appropriate for your machine type (textured for external, smooth for chamber). Ensure they are BPA-free and freezer safe.

- Prepare Food Properly:

- Pre-Chill/Freeze: For liquids or very moist foods in an external sealer, pre-chilling or partially freezing can prevent liquids from being drawn into the pump.

- Clean Rims: Before sealing, wipe any moisture or food debris from the inside of the bag opening to ensure a perfect, uninterrupted seal.

- Avoid Overfilling: Leave enough space (at least 2-3 inches) at the top of the bag for a strong, flat seal.

- Position with Care: For chamber sealers, lay the bag flat in the chamber, ensuring the open end is clean and aligned correctly over the seal bar. For external sealers, ensure the bag is properly inserted into the vacuum channel.

- Regular Cleaning and Maintenance:

- After Each Use: Clean the sealing bar, drip tray, and chamber (for chamber sealers) to prevent food residue buildup.

- Inspect Gaskets: Regularly check the rubber gasket for cracks or wear, as this is crucial for maintaining a tight vacuum.

- Oil Pump Maintenance: If you have an oil pump model, follow the manufacturer’s guidelines for checking and changing the oil. This is vital for its longevity and performance.

“Proper maintenance is non-negotiable for a commercial vacuum sealer,” says Clara Jenkins, a seasoned Food Service Operations Consultant. “It’s not just about keeping the machine running; it’s about ensuring consistent food safety and maximizing your investment’s lifespan.”

Beyond Preservation: Unlocking the Full Potential of Your Vacuum Sealer

While extending shelf life is a primary benefit, the best commercial vacuum sealer offers a multitude of other applications that can streamline your kitchen operations and elevate your culinary creations.

Sous Vide Cooking Preparation

Perfectly sealed, airtight bags are essential for sous vide. Vacuum sealing removes air that could cause bags to float, ensuring even heat transfer and consistent cooking results.

Rapid Marination

The powerful vacuum opens the pores of food, allowing marinades to penetrate much faster and deeper than traditional methods. What used to take hours can now take minutes.

Portion Control and Inventory Management

Seal individual portions of proteins, vegetables, or prepared meals. This simplifies inventory tracking, reduces waste from oversized portions, and makes meal prep a breeze.

Infusion and Compression

Vacuum sealers can be used to quickly infuse liquids into fruits or vegetables, creating unique textures and flavors for modern gastronomy. They can also compress ingredients, altering their texture and intensity.

Non-Food Applications

Don’t limit your commercial vacuum sealer to food! It’s fantastic for protecting important documents, valuable electronics, camping gear, or even medical supplies from moisture and oxidation.

Frequently Asked Questions (FAQs)

How long does vacuum-sealed food last compared to conventional storage?

Vacuum-sealed food can last significantly longer, often extending shelf life by three to five times. For example, fresh meat typically lasts a few days in the refrigerator but can last up to two weeks when vacuum sealed, and even longer in the freezer without freezer burn.

Can I vacuum seal liquids with an external vacuum sealer?

Generally, no. External vacuum sealers struggle with liquids because the liquid can be drawn into the pump, damaging the machine and preventing a proper seal. Chamber vacuum sealers are specifically designed to handle liquids effortlessly.

What’s the main difference between an oil pump and a dry pump in commercial vacuum sealers?

Oil pumps are typically found in high-performance chamber sealers and are known for their extreme durability, consistent vacuum strength, and ability to handle continuous heavy use. They require regular oil changes. Dry pumps are maintenance-free but are generally less powerful and less suited for constant, high-volume commercial operations, often needing cool-down periods.

Are commercial vacuum sealer bags reusable?

While technically possible to wash and reuse bags if they haven’t contained raw meat or oily substances, it’s generally not recommended for commercial settings due to hygiene concerns and the potential for compromising the seal quality. For optimal food safety and consistent results, single-use bags are preferred.

How often should I clean my commercial vacuum sealer?

It’s best practice to clean your commercial vacuum sealer after each use, especially the sealing bar, drip tray, and inside the chamber. Regular inspection of the gasket is also crucial to ensure it remains free of debris and in good condition to maintain an airtight seal.

The Freshness Advantage: A Smart Investment

Investing in the best commercial vacuum sealer is more than just buying a piece of equipment; it’s adopting a strategic approach to food management that pays dividends in freshness, efficiency, and cost savings. From preserving delicate ingredients to streamlining your sous vide preparations and reducing costly waste, a robust vacuum sealer empowers your business to operate at its peak. So go ahead, explore the options, find the model that fits your needs, and take the plunge. Your kitchen, your ingredients, and your bottom line will thank you.